Remove plastic wrapping from Optiweigh unit.

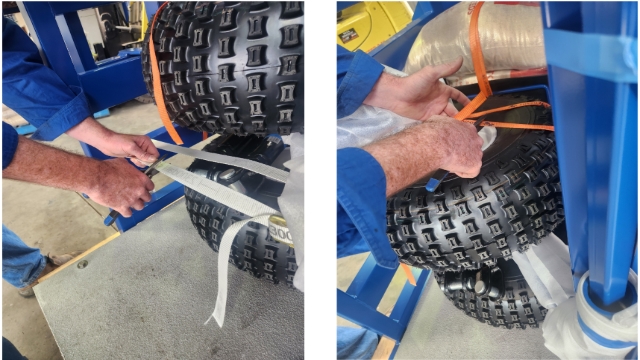

Remove the straps securing Optiweigh unit to pallet and begin removing the wheels and axles.

Remove the bolt and washer from the bottom of the axle bar, you should then be able to slide the axle bar out of the wheel axle.

Slide the wheels into the axle tubes at the front of the machine. Insert Axle bar and tension bolts (19mm)

Attach the top links to the unit and wheel axles. Ensure the nut on top link is closest to the unit.

Lock the bracing bar from the drawbar into the front of the Optiweigh unit using the clevis pin.

The force panels and lick tray can be adjusted depending on the class of stock being weighed. The purpose being to ensure only 1 animal on unit at a time.

Lick Limiter is to be sat on top of loose lick.

Use ratcheting top link to jack unit up and down. The toggle circled in image changes direction of top link.

Connect unit to tow ball and continue jacking until sufficient clearance. It's recommended to not exceed 40km/h.

Ensure solar panel is facing North and the unit is positioned on a reasonably flat surface with nothing impacting load bars or platform.

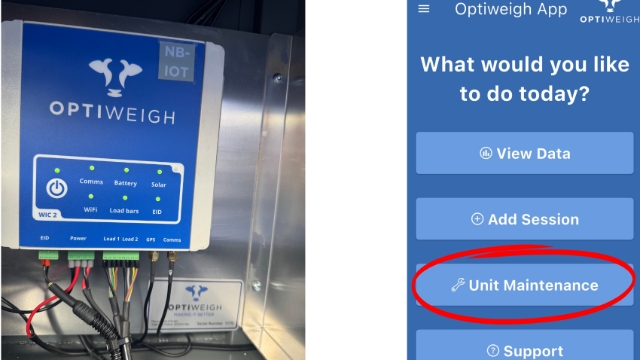

Before deploying Optiweigh unit ensure all lights on the WIC2 box are green. This is good opportunity to use the app to check unit.